Polyfuel Group Limited

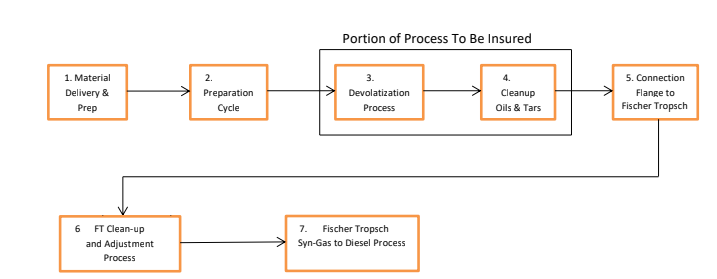

Process Flow Chart

Materials are delivered to facility. The materials are separated by calorific value, dried and size reduced. The material is fed into the retorts in such a way as to achieve steady state. Gases are manipulated in favour of higher methine. Sulphur and Aromatics are removed from the gas. The ratio of hydrogen to carbon gases are corrected. The carbon chains are grown in the Fisher Tropsch and synthetic diesel id produced for the gases.

One of the unique capabilities of this technology is its ability to produce water if required. As we have an excess of Hydrogen gas, we can sell Hydrogen gas, or we can add oxygen to the gas to produce water. In this case we can produce circa two litres of water for every one litre of Diesel produced.

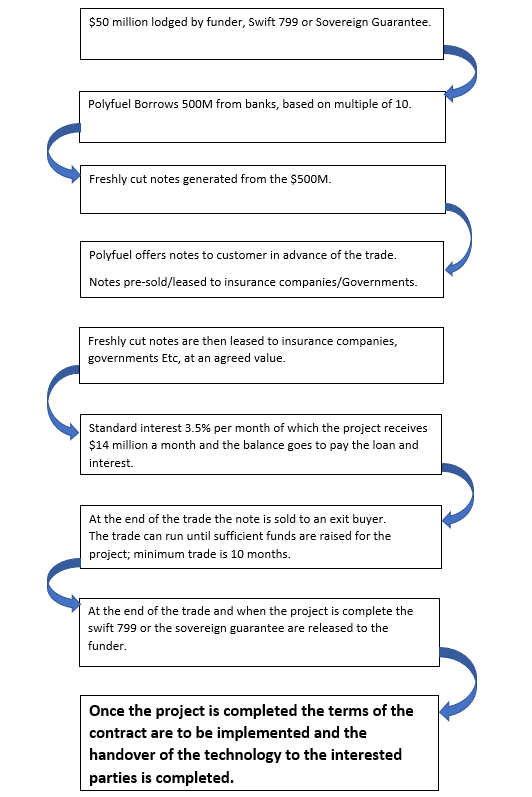

Polyfuel Group Limited recognises the challenges experienced by rapidly growing economies and uses a unique humanitarian fund raising system that reduces the financial burden on the customer.

Latest Post

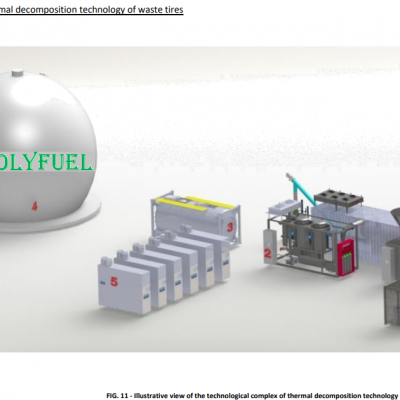

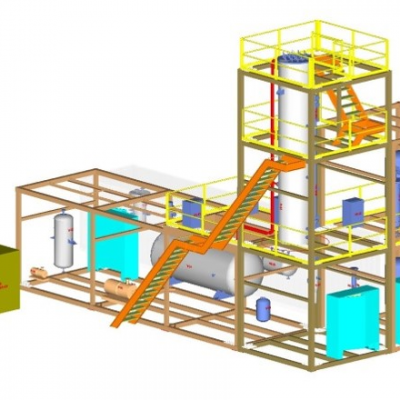

The thermal decomposition of a selected segment of waste materials in the containerised solution.

It won’t be a bigger problem to find one video game lover in your neighbor.

Thermal Treatment of Waste

It won’t be a bigger problem to find one video game lover in your neighbor.