This is the newest and latest development/ addition to the Polyfuel family of waste solutions. Polyfuel would like to present a basic range of information and a proposal for the solution of material utilization of selected waste materials, i.e.:

- sorted waste plastics in the crushed form:

- The emphasis on the advantageous ratio between the input power of the technology, the amount of plastic waste disposed of, and between the amount of liquid fraction obtained.

- Emphasizing the maximum yield and the highest quality of the liquid fraction during thermal decomposition of the material at the expense of input power, or

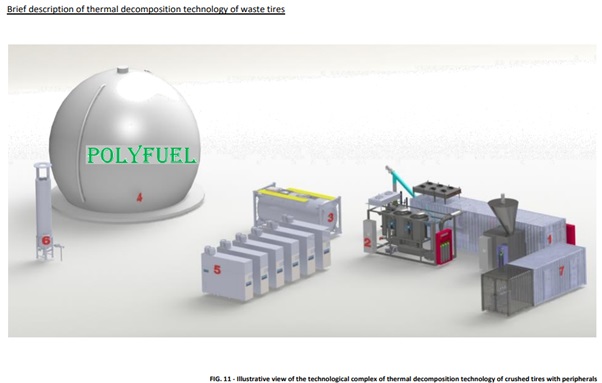

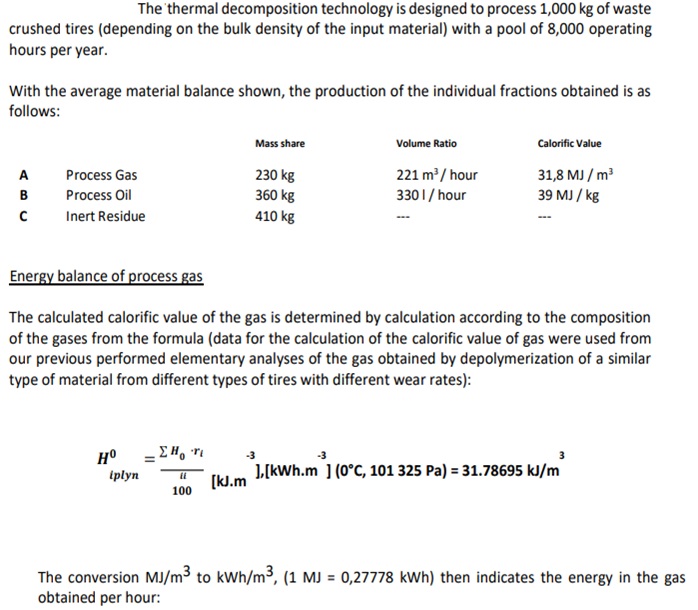

- material and energy use of crushed waste tires in the form of thermal decomposition, including possible peripherals to the core 17/24 tonne range.

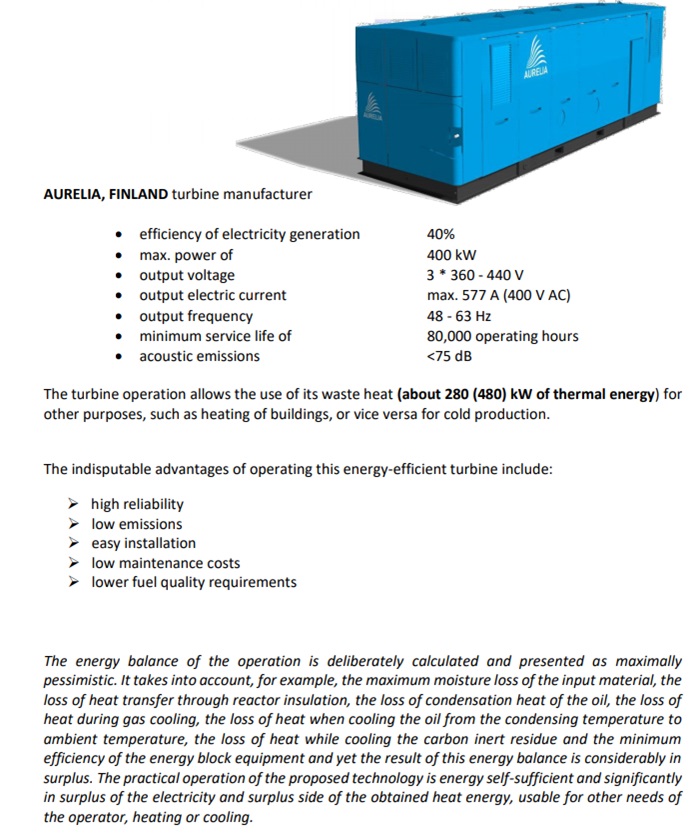

This technology will process 24 tonnes per day of tyers or 17 tonnes per day of plastic. The end product is Diesel, power or a mixture of both. The technology has no requirement for a chimney and can supply all its power requirements.

For safe, economical, and reliable operation of the proposed technology, it is necessary to observe the basic parameters of the input material:

➢ essential decontamination of foreign impurities, without the presence of oversized pieces of mechanical impurities, stones, and other solid inert materials

➢ maximum crushed fraction size ≤ 35 mm in each axis

➢ maximum PVC content in the mixture ≤ 3%

➢ maximum surface moisture ≤ 10%. A considerable amount of energy will inefficiently subsidize the thermal decomposition of material with higher humidity. The result of thermal decomposition will be of lower quality, and the solid residue (carbon)will contain a high percentage of volatiles

For this option, the technology is equipped with 600 * 6.000 * 8 mm reactors and heated by economical high-frequency induction heating with active electronic thermostatic regulation. The total installed power input of the technology is 520 kW, the operating electricity consumption is at a maximum output of about 330 kW / hour.

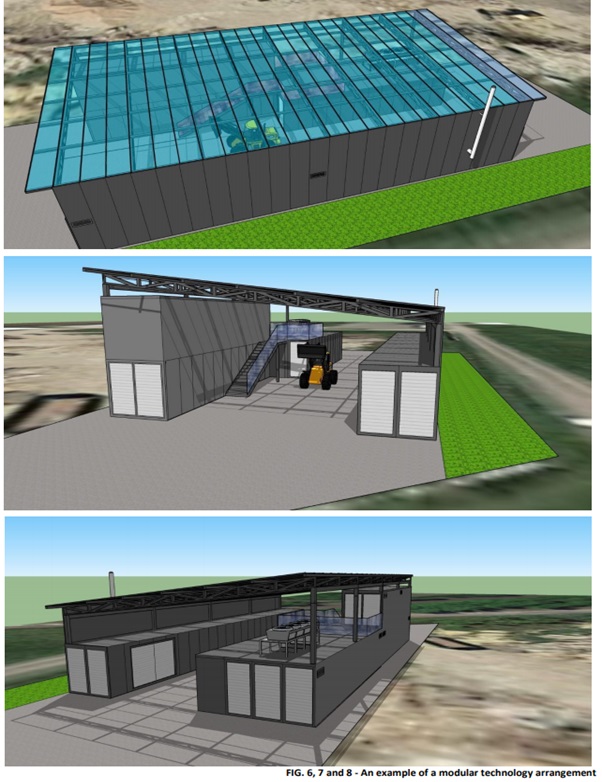

The generators and oil storage can be containerised, as seen below.